-

Content Count

2,300 -

Joined

-

Last visited

-

Days Won

36

Content Type

Profiles

Forums

Gallery

Blogs

Calendar

Store

Posts posted by MikeD

-

-

4 hours ago, G O B said:

I have 1st class mags from BOTH vendors. BUT... they are as DIFFERENT as AK/AR.

I wish you both well, and keep doing what you do.

Does liking both polly and steel make a person bi-magual????

You aren’t alone. I swing both ways too. (Magually) 😂

-

Lol! Hopefully that’s what it means! Always use eye protection!

-

5 hours ago, TXscooterguy said:

Everyone see those 2 pits on the bolt lug? That’s where they tested the hardness of this bolt. I’m willing to bet these aren’t anywhere on those TriStar guns or other Chinese or Turkish clones... Why would they bother when they know they don’t care anyways, lol.

-

I don’t think they sell them as spares. Yeah, the 4th setting can’t let in anymore gas than the 3rd setting can so nothing to gain by using the 4th. You can get a touch of extra efficiency if you weld up the 4th setting to decrease chamber volume. Just clean up the outer diameter good or stand off from it a touch. You should notice that it ejects the low brass with a touch more force after that.

-

Actually you really only have 3 ports with that plug. The off setting is not truly off. It should tried first with your high power and heaviest of load. The 4th and largest setting isn’t gaining anything over the 3rd setting. The 3rd setting is way larger than the ports in the barrel can feed as it is. Just having that huge 4th port there actually hurts the efficiency of low brass regardless of on the 3rd of 4th setting because it adds a chunk of chamber volume to fill with gas. It would be a better plug if it wasn’t even there or welded up. The number 2 setting is good for a lot of high brass but still a little too much gas for some rounds that won’t operate off the 1 setting. If you add an extra detent with a mill, drill press or dremel just off the detent that the 2nd setting uses you can slightly turn past it and close it off a little and make an extra setting for that ammo. If you do the detent should basically meet the edge of the 2nd settings detent.

-

I’m dying to get one myself. Hopefully I don’t regret holding off on one but right now I just do t want to do it to myself. Too much other stuff going on. I fear if I get one I will spend a week anylyzing every detail I can of it. I have problems, lol.

-

I asked them if the gun had been modified and they said it was new in the box gun. I asked them if they were sure it wasn’t the trunnion and they didn’t know what part I was talking about. I clarified but haven’t heard back.

Salty, does the cover come off easily or do you have to remove the shell to disassembly it? I saw it has an adjustable gas plug under the shell. Do you have to remove the shell to adjust it? Did yours have a hole through the lug channel on the bolt carrier?

I am almost suspecting they were firing it on the low brass setting. Still doesn’t seem it should have done all that though. Tons of Saiga’s get hammered on with incorrect settings and Veprs hammer themselves with high brass. Never seen this out of them...

-

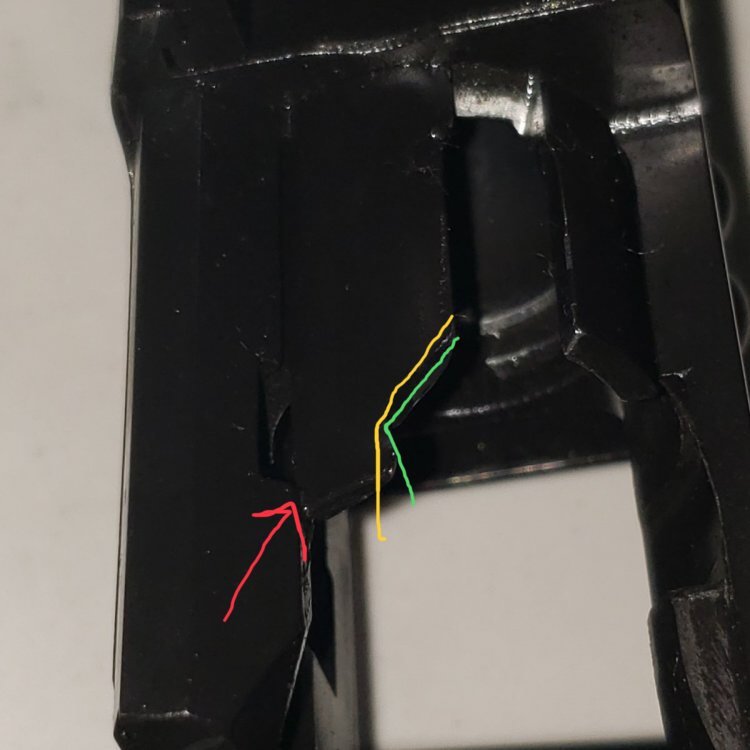

Yeah, I was wondering about the lugs too because even if one broke there should be one left. Was also wondering about how it could have an out of battery discharge. Don’t have a TriStar to look at. Maybe Salty can look at his. Hopefully more info will come out on what really happened here.

-

Salty, can you see through the lug channel on your carrier? Wondering if they are made like that or if this one blew. It looks awful jagged in the pic...

-

-

-

I like the looks of the PSA but just don’t feel any of the other 9mm AK’s I’ve seen. I hate the look of the Glock mag ones.

-

The market being so down should really help bring new items and innovation. The 9mm AK’s from K-USA should be a damn hot seller. Little pricy right now though... Their next step is going to be a AK-103. I think that is a mistake. They should have focused on an AK-107 if they wanted to wow us. I can only yawn at another 103...

The shockwave was a huge success. They sold 50,000 or so in the the first 8 months of it’s release. New and cool... They need to get a magfed semi released. Bet they would easily sell 100,000 or more the first year. Hell, maybe that many of a semi magfed shockwave configuration alone...

-

1

1

-

-

37 minutes ago, kindapointless said:

I'm so in on any drum like that Mike. I love my lil 12 rounders unfortunately both the ones I have now seem to have too much spring pressure when full, i have to shove the bolt forward to even chamber the first one

You could mark the hole in the sprocket the spring is at now and count how many times it is wrapped as it unwinds. Then try to step the spring down a step at a time with the holes in the sprocket. It should be somewhat adjustable. The smaller diameter sprocket requires less force to pull the rounds compared to a 20rd drum. Chances are they are putting the same amount of turns on both their 20 and 12rd drum.

-

Yeah, that’s the kind of projects I live for...

-

That is a really cool project and he should be very proud of it but hell no, lol... Nothing like that. I would never consider an open design for one. Or a design that ended up being so heavy. That things is almost as heavy empty as it should be loaded... Even with some weight reduction it will likely still be overly heavy. I fear he is going to run into friction issues as well with his design. Actually he already is it appears. He is likely having the FTE because he needs so much spring pressure to feed it. He states he still doesn’t think he has enough pressure for the last few rounds. So it will likely get worse when he adds more spring pressure. I do hope he can work it out though and make himself some money. He has some serious challenges ahead. I definitely won’t say impossible though...

I first made a high capacity prototype almost 5 years ago. It will be 5 years on April 1st actaully. Took about 10 days from there to get it 99% thought out and refined. The first was a drum the same size as a current 20rd drum that holds 33rds instead. It’s empty weight is only about 2 ounces more than a MD-20. I recently filed a patent on it but it won’t be publicly viewable for awhile yet. The patent is key to getting around friction issues and some other issues I won’t discuss yet. I won’t say there aren’t other ways but they won’t be easy to figure out and my patent applications covers all the ways I could think of to over come them. The new design will make all prior drums as obsolete as a double stack makes a single stack... 33rds in the old 20rd size and 20rds in the old 12rd size is going to be hard to contend with. They are still a ways off but it’s not going to take as long to bring them as it was for a double stack.

Really doing both 2 3/4 and 3 doesn’t add much to the challenge. I had to skip 3” on the MD-20 but that’s because I was running out of prototype money to work past them. There was a design flaw in the gun I identified at the time that compounded issues but that has been fixed in the guns since.

-

What if a drum the size of the 12rd actually held 20rds?

-

It all depends really. Some materials in FDM are only good for around 10rds. Others are good for a few hundred. Print orientation plays a big part in FDM strength and durability. So many factors contribute and play a part in FDM parts. I could write a book on it trying to go into them all and barely scratch the surface.

SLS is much stronger than FDM. It’s still no where close to injection modeled strengths and durability but typically light years stronger than FDM processes. Rather expensive though.

The recoil of a 12ga is really hard on printed parts that hold so much weight... Great for prototyping but just isn’t there yet for any prolonged use.

-

All but the 21rd I made myself with a FDM printer. The 21rd I hired out to be made on a SLS printer.

-

Sounds a little cheap. I’ve seen them go for $2500 used...

-

1

1

-

-

Get them to squeeze in a Dayton show, lol.

-

1

1

-

-

-

Is the camming lug on the top of the bolt showing bad impact or deformation?

-

What is it with Chicago?

in General Discussion - Any topic is welcome here!!!

Posted

I don’t think you have to worry about the country dividing. The most likely senerio is we kick the shit out of those areas and when the dust settles they emerge from their basements with a whole new level of I better shut the hell up. You have all heard the sentiment growing. A very large percentage of their supporters won’t fight for themselves let alone a nation or idea. We are the working class, we are the farmers, we are law enforcement, we are the military, we are the gun owners... They are the pansies, the felons, the lazy, the dependents...