Veprz

-

Content Count

178 -

Joined

-

Last visited

-

Days Won

15

Content Type

Profiles

Forums

Gallery

Blogs

Calendar

Store

Posts posted by Veprz

-

-

-

Bolt held open, full mag, safety off.

-

On 10/4/2018 at 9:10 PM, usdmatt said:

I emailed them on the status of the repair and they say 1 more week before it ships back to me ! Will post when it makes it here.

Nice! Good news.

-

-

45 minutes ago, evlblkwpnz said:

I definitely have access to a CNC mill. I do a lot more than what people see here. I do some AK rifle work too, but being a one man shop I can't compete on kit build pricing from the major guys who have employees doing the work. For now, it is a matter of finalizing the closure of my other company and catching up SBS work. After that I can focus on product and marketing. I have been doing all I can to keep things throttled down until I am free of the other company. The past 5 years have been exhausting running two companies in different industries, but I am almost done with it and I am excited to be closing one chapter and moving on to the next.

I could imagine how hectic that could be. Your work speaks for itself and Im sure your products will be a success. Best of luck and keep us posted.

-

1

1

-

-

On 9/3/2018 at 10:34 AM, evlblkwpnz said:

Now that I know how to program a CNC mill, as soon as my pool company is closed and I catch up on custom work I am going to start on my long list of product offerings. That adapter will likely be the first offering. It won't be $80 like the barely working adapter Pauly was going to offer. Mine works and the price will be sane.

Do It! You have or have access to a cnc mill? I know the S-12's/V-12's are your thing but do you do AK work? As in rifles?

-

On 8/23/2018 at 11:25 AM, G O B said:

Looks like drums will become unwieldy at around 25 rounds, and impractical under about 10 rounds. 10 round double stacks would go well with that drum.

Vepr-12/Saiga-12 drums and doublestacks, what shouldve been..

-

On 8/23/2018 at 10:47 AM, CRZ said:

So I've been an occasional lurker at best, but I'm extremely curious what the OP might need to create a prototype run of these.

I've been wanting a drum mag, but these enormous oversized 25 rounders on the market are not appealing to me. This is certainly superior, and if we could convince MikeD to make some I'd be in for a couple of them.

But I'm also interested in 10-12 round drum mags for the VEPR. Is that a pipe dream at this point?You could always use evl's trick to run S-12 mags and drums in your V-12.

-

21 hours ago, usdmatt said:

I let time get away from me working overtime and purchasing some furniture etc. I mailed out the firearm on 7/20 and apparently there was an issue delivering the package and it sat at the post office for 3 weeks. However, earlier i received confirmation from KUSA that the package has arrived. Will post update !

Thats good news! At least they are taking it in, hopefully they will get you right.

-

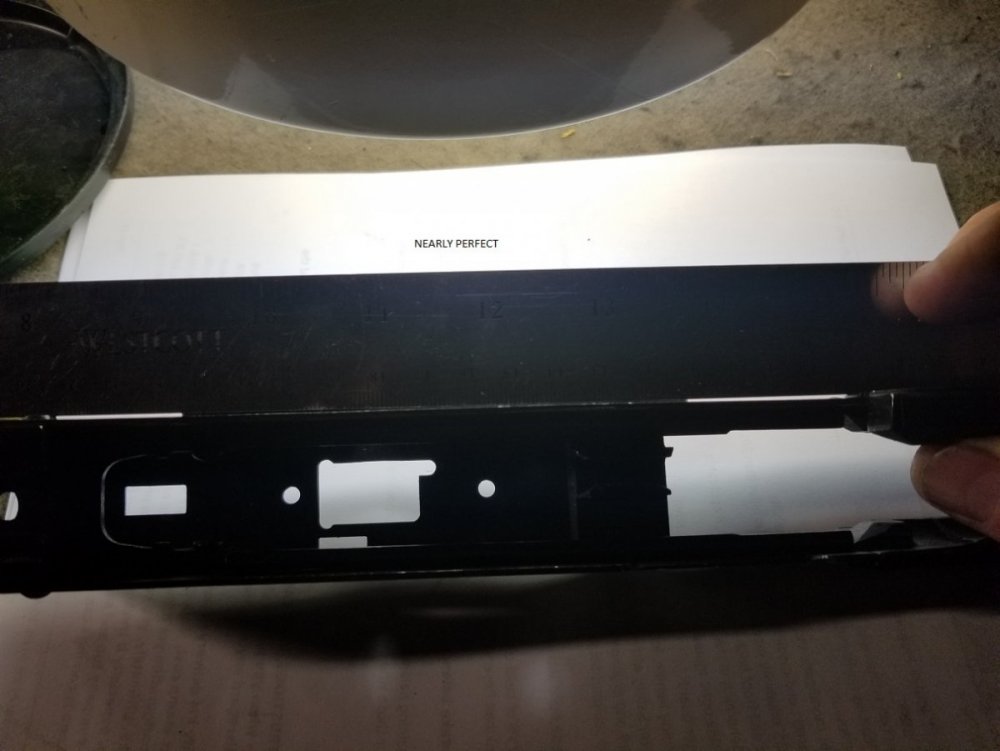

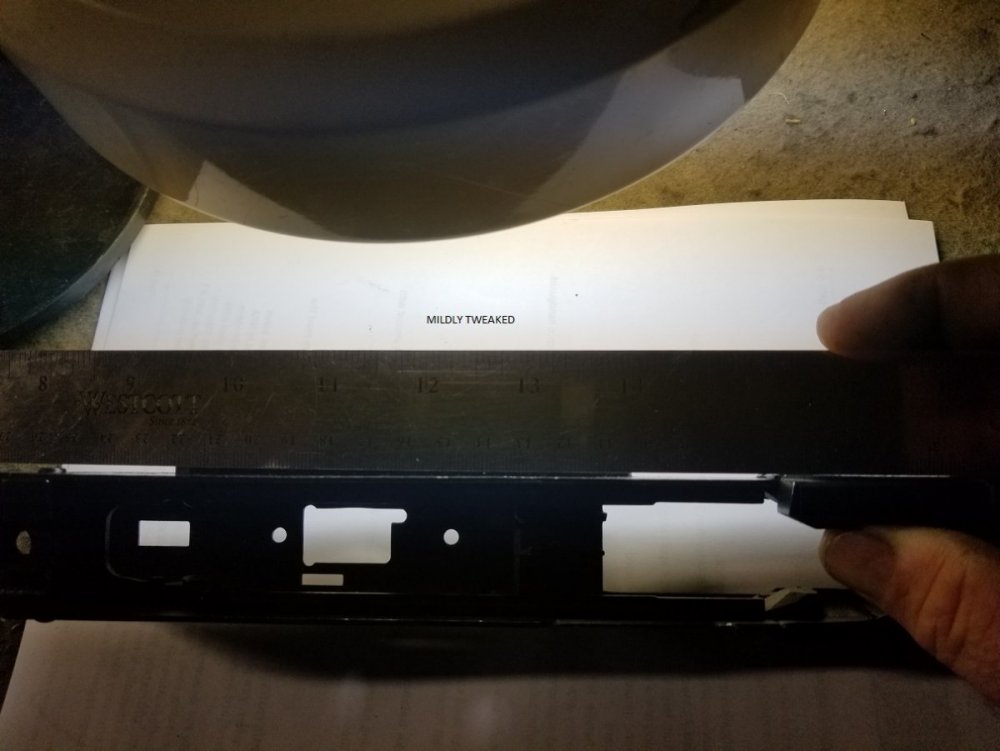

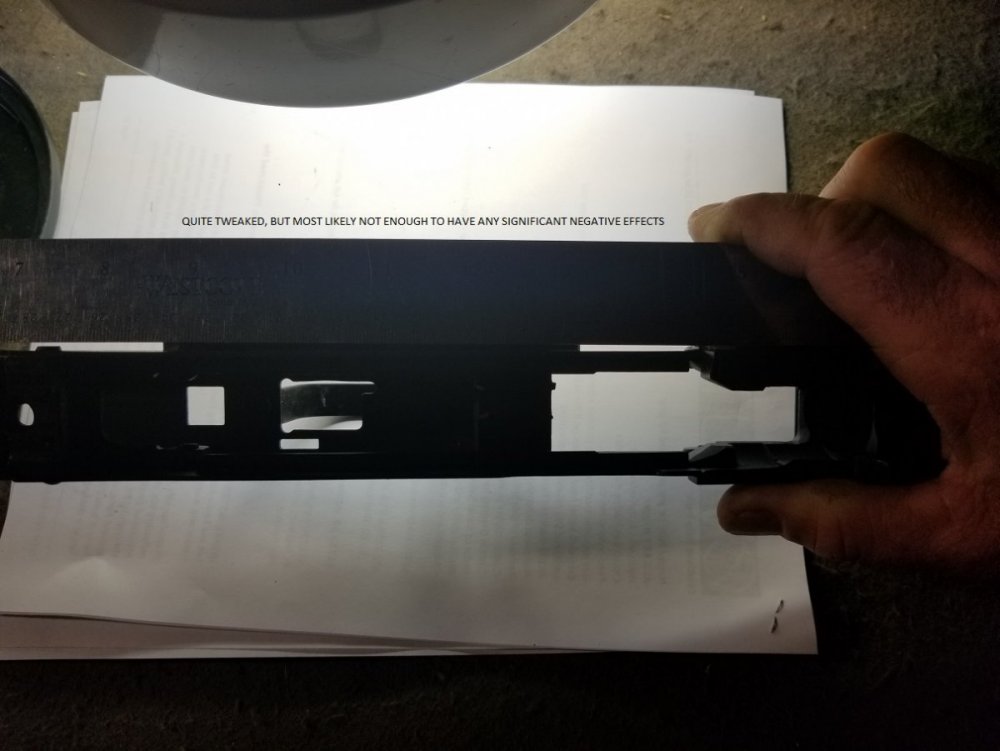

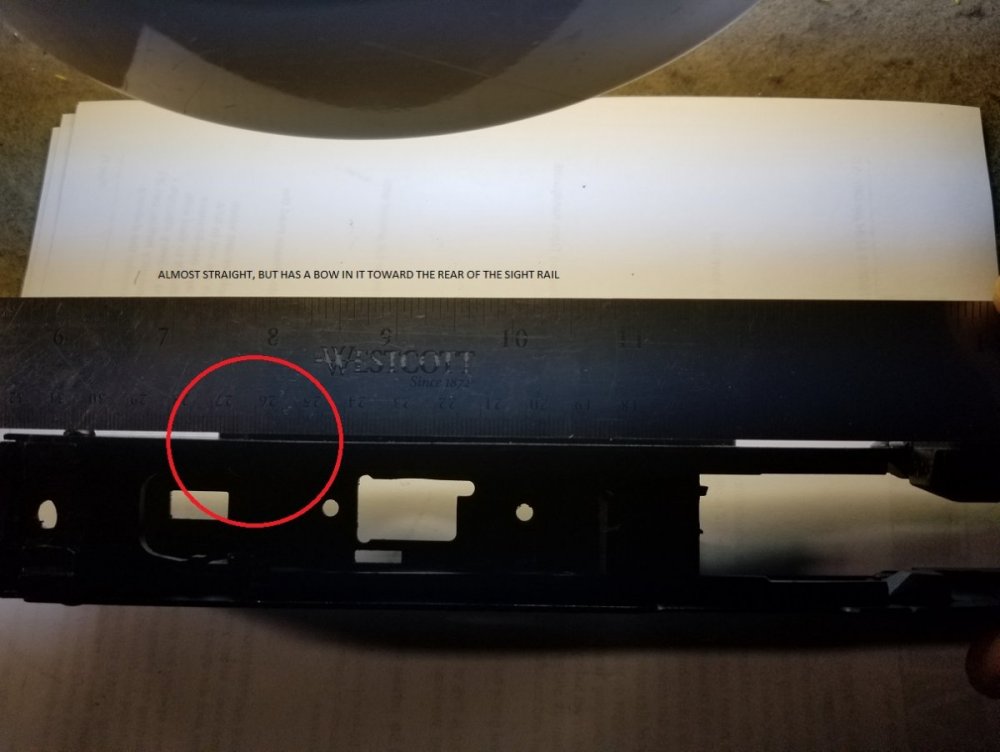

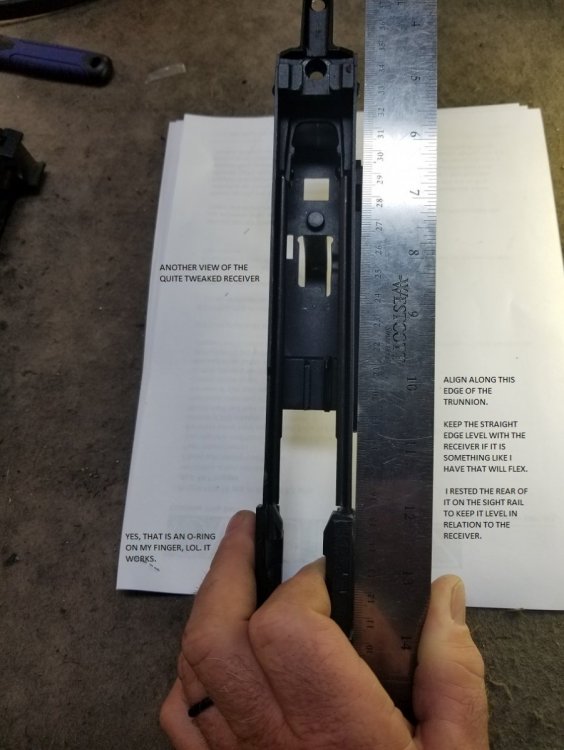

All your pics with the new metal straight edge are good. I can clearly see warping/waviness around the hammer, trigger and safety. It also appears that the receiver is tapered.

-

There is definitely a bit of warpage in that receiver. How bad that really is? Ill let the experts decide.

In a perfect world you would see no gaps at all running all the way down the receiver forward to aft.

-

9 hours ago, evlblkwpnz said:

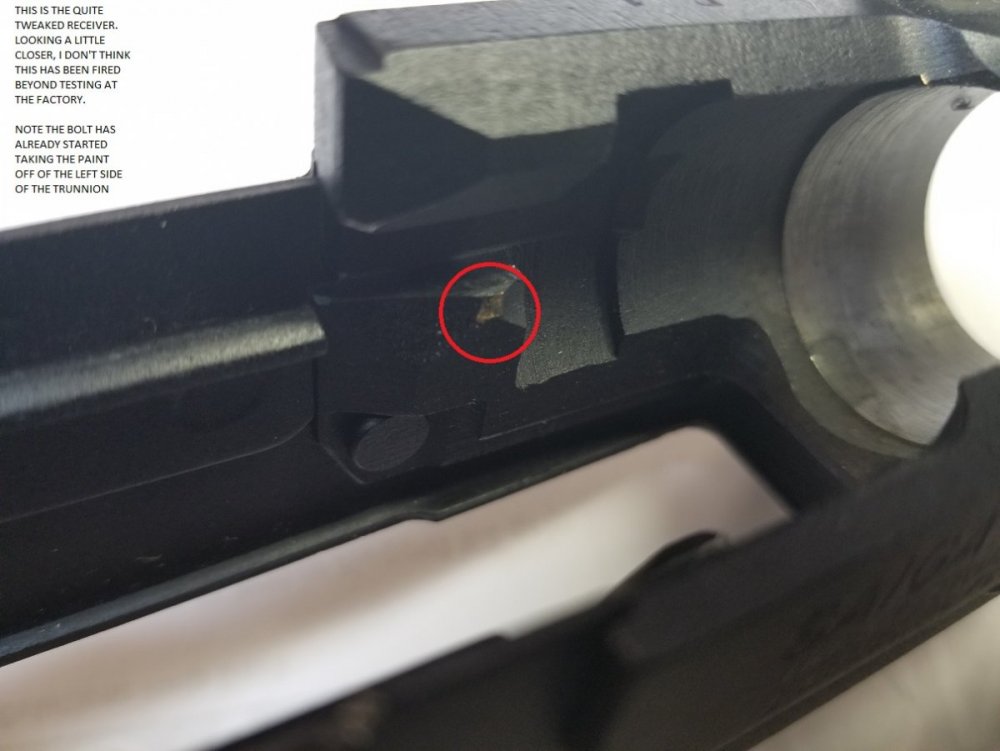

Wow! That receiver in the 5th pic looks warped to hell!

That gas block pin channel in your next post..SMH! I know theres not nearly as much material as on a AK barrel but dang!

-

1 hour ago, evlblkwpnz said:

I just took a really good look at 3 receivers. 3 were almost straight and one was drastically bent to the left at the rear. The bent one was hardly fired before it came here and has the most evidence of the bolt head striking in the receiver at the trunnion of the four. One has seen at least two owners that fired it and has very little evidence of the bolt head striking the trunnion. That one was almost perfectly straight. I was quite surprised. When I settle down tonight I'll try to post some pics. I have a lot of machine work to do today and my wife is out of town, so I may end up making a marathon of it and then pass out. Hard to tell. When the cat's away, the mice will play all night. I wonder how many other people are looking forward to working into the night on Saturdays? I do love it and I wouldn't want to be anywhere else.

When you're doing what you love is it even considered work? Lol. I guess it still is when you're working on other peoples stuff.

Did the bent receiver exhibit deformation in the same area as Kwesi's bolt?

-

14 minutes ago, kwesi said:

Yes. No return call.

I got them on the phone today and spoke with a salesman. He said they will have parts availible at some point but they are not availible now. I mentioned that having carriers, bolts and magazines availible for sale would be great for them considering how many S-12's and clones are out there and utilize the same parts and mags. He agreed, not suprisingly. They could be making money selling parts to people that dont even own a KS-12, its a no brainer. Think about how much $$$ glocks making selling just magazines? With all the different carbines that take glock mags.

The guy said the parts will be for sale on their website once theyre availible, and also said not to expect them for 6+ months from now.

-

Well on a positive note, it looks like you have a clean and well organized work area.

-

1

1

-

-

4 hours ago, kwesi said:

The one spot that I did notice was the small red circle. Are you suggesting to take a small file and slowly knock off the burrs? I can probably handle that.

I believe evl was pointing out that there has been contact there and that is where the peening is occuring. Also I believe he's wanting to see a pic as described in his drawing to try and determine if the reciever is bent at all.

So lets say if the reciever was slightly bent, causing the peening/deformation..then filing that circled portion wouldnt actually fix the problem. I would hold off until he gets a chance to see the reciever, thats just my opinion.

-

4 hours ago, kwesi said:

A big thanks to all who are sharing their expertise. I will need to sit down with the S12 and slowly read these posts over so I can hopefully get you the photo's requested. It's just that my mechanical abilities are growing...

Youve got to crawl before you walk, or if alcohol's involved you start walking but end up crawling lol.

The biggest thing when doing any kind of mechanical, electric or metal work is to take your time. Speed comes with experience. You dont want to rush because thats when you make mistakes.

Its always easier to remove more metal/material than it is to add metal/material back. When it comes to metal work such as fitting parts I always prefer the least aggressive method that will still be effective..I.E using a file v.s. a dremel because although its faster its also much harder to control the amount of material being removed and much easier to go overboard.

A dremel is great for things that arent critical and/or hard to replace.

-

11 hours ago, evlblkwpnz said:

I have been too busy to have a really good look at the parts on this KS-12 compared to a Saiga-12. I may do a little part swapping when I start testing the KS-12. I do have one non-relocated Saiga-12 that I keep forgetting that I have. I can compare it directly to the KS-12 and swap to see how things feel and work. It was the one in my first 100, 200, and 300 round dump videos when doing work for others was but a twinkle in my eye.

That would be valuable data and much appreciated.

-

9 hours ago, kwesi said:

I left a voicemail at KalUSA today re: available bolts, carriers, springs, etc. and to confirm they are interchangeable with our S12.

Reeeeaaaaallllyyy?....very interesting! Your talking about K-USA (as in the manufacturer of the KS-12)?

-

Damn bro, you've got the triple threat dream team on the case lol! Youre in good hands.

-

1

1

-

-

On 8/5/2018 at 3:46 PM, kwesi said:

I don’t mind what it looks like as long as it functions and is not causing additional damage to other parts. I’ve started getting stovepipes not only with Federal Bulk but also on Remington Sluggers ( never have issues with them ). Long story short: after much testing it seems that my forward recoil spring is bad. Last test was with the Gunfixr plug set on 3 and a Carolina Supply Low Recoil Spring. The Fed bulk ran 100%! I’m thinking the peening is not the problem. Thoughts?

The peening/deformation is note worthy but not extreme at this point. Whatever is causing it too deform may be the cause of your stove pipe issues also. The recoil spring could be a contributing factor in the stove pipes also. Are the gas block, plug, gas puc and actual ports clean and allowing the proper amount of gas to the action?

-

If its not causing any problems you could probably just leave the peened/displaced material. If you currently have or start to have issues with the shells rim not being properly held by the extractor (as described by Tony), then you would need to lightly file the peened/displaced material flush with the face of the bolt. You can test this with the bolt out of the gun and a fired shell.

Besides that if its not causing a function issue, its really would come down to how much it bothers you looking at it.

If you do decide to file away the peened/displaced material, you want to take it slow..ONLY remove the peened/displaced material flush with the face of the bolt and stop before affecting the base metal (the reason why I wouldnt suggest using a dremel). It really will not take many strokes or much pressure to remove that amout of material (very light stroke with basically no pressure applied, let the file do the work). As far as the side of the bolt head the same basically applies, but since that surface is intended to be rounded you want to make sure you dont file so much as to create a flat spot. In other words you want to keep the same profile/geometry as how it came from the factory. Do not roll over the edge (bolt face to side wall of bolt) do one edge at a time, seperately.

Id like to see what evl thinks about the reciever when hes sees the pics.

-

2 hours ago, evlblkwpnz said:

V12 bolt will swap right in.

Take a picture from the rear of the receiver, centered, so I can get a good look at both rails at one time. I think your receiver may be bent, more than usual, to the right at the rear just behind the trunnion. Has the weapon been ran with springs other than factory springs or ran on wide open gas setting with strong loads? While trying to break a carrier repair I bent my own receiver a whole back with Remington Express 3" 00 buck on the wide open setting. It took quite a bit of rounds to do it over multiple testing sessions, but I had all of the factory springs in place and it was done with a chopped carrier (lighter) in the weapon. The carrier repair never broke, but I did have to take the weapon down and straighten the receiver. It wasn't very difficult, but I could see it going wrong if one is not skilled.

Youre killing me with this talk of carrier repair that can take extreme abuse!! Lol. When are you going to offer this service as a repair/or preventitive measure?? If you decide to never offer it as a service, please share a description of the procedure as Im sure alot of people would be very interested.

-

12 hours ago, kwesi said:

I just stopped by my buddies house to take a look at his S-12, his has a mark in the same spot on the bolt head thats much less pronounced (round count around 200-250 rnds). When I took the top cover and recoil spring out and slowly hand cycled the action, I observed that that part of the bolt head is inline with the upper left (looking towards bore)tang (for lack of a better word) of the trunnion. It didnt appear to make any significant contact while slowly cycling. But if I put slight lateral pressure on the bolt (from the side) it would contact the trunnions tang on the way in. I believe this is where the peening/deformation is occuring. Why its happening? Im not sure. Theres obviously a misalignment but is it because of loose/sloppy/worn fit ,A slightly out of spec bolt head (clearencing itself), or possibly a bent reciever as evl suggested?

My buddies S-12 did have a little play in the bolt stem to carrier channel fit but not much, his has a very low (200-250rnds) round count of mostly federal bulk pack birdshot through it. Unconverted,Everything is factory.

Your bolt will hang up at the very end of its travel, just before its completely in battery. That is normal. The bolt will hang up when hand cycling slowly because the bolt needs to overcome extractor spring pressure to interface fully with the extractor slot/channel. When you pull it back and let it slingshot or during firing recoil spring pressure along with momentum will easily overcome the extractor spring and go fully into battery without issue. The bolt shouldnt hang up anywhere else if everything is functioning normally.

So I un-TROMIXED my Tromix S-17.

in Saiga-12

Posted

That looks great! What magwell are you using? And what was involved in the installation?