-

Content Count

2,817 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Blogs

Calendar

Store

Posts posted by dinzag

-

-

Thanks for your support!

-

Shirts look great Juggs, thanks!

Thanks for all your & momma Juggs legwork in getting those cranked out!

Mucho appreciated!

-

If the bolt is not picking up your rounds at the base of the cartridge, that is your problem.

Just for quick analysis, pull the mag rearward and up in the rear, then cycle & see if it does the same.

Compare with the factory mag as well, push the rear of the mag up to make it simulate a longer catch.

-

Thank you for the support guys. Here's a few additional tidbits. (GOB beware - it's a little wordy)

The Saiga 308 is an oddball application, hence the price - $80. There's several extra mods to them to make them a true drop in. Build up material to engage safety, cross member relief, hammer face rework, bho relief, hand polish every contacting surface, refinish. All of the factory Saiga hammers have a chamfer at the rear and it really affects cycling and assembly. Notice on the plain G2's they have a rounded hump back there, many times it will hold the bolt back cycling by hand. Also the factory 308 triggers have sheetmetal spot welded over the trigger body which in turn requires a larger hole in the receiver. Tossing any ole' trigger in there you should notice it floating left to right. That is addressed as well.

The RSA 308 adjustables are nice and you can get them dialed in pretty sweet. You do need to address the trigger floating (which can jam up the rifle or break the hook on the trigger) and cut clearance in the hammer for the Saiga BHO lever. The Saiga-12 & 308 ones listed on their site are identical to the VEPR-308 ones. They do have the cut for the cross member and taller trigger legs for the safety.

If Tromix's 308 FCG drops right in, requires no mods, then by all means buy from him. I can't make them for that cheap.

I totally rework and polish them all by hand. No parting lines and all contacting surfaces are smoothed out. Then they are washed & degreased, baked & refinished. All the other PG converted Saiga FCG's are $55 each. Only the PG converted 308 set runs $80.

If you want to do the mods yourself, I also offer unmodded G2's, the Arsenal FCG's and the RSA's will be up shortly as well.

All will come with disco spring, e-clips & hitch pins. Tony also sends a retaining wire and disco spring with his.

-

I think if he takes a little wider survey he will find that they range anywhere from 0.695" to 0.720".

The majority of older ones were around 0.710"+/-0.005".

I quit making them for that exact reason.

I have about 30 FSB's that I have collected over the years and they were all fairly consistant until RAAC started bringing them in.

Be careful with them guys. Loctite them on, check screws often.

-

Fine choice for a mod, congrats Doc!

-

They go out Monday bff

-

-

http://www.ironwooddesigns.com

Give Matt a shout here soon. I'm waiting on him to finish my 100 series 30-06 stock set and he's sending me HG's to machine out so he can tool them up & make Saiga specific stock sets. His standard AK stocksets will fit the x39's & 223's.

-

Yeah they are custom made and not cheap.

My Atlas will turn metric threads but I prefer using a tap.

Shoot me an email if you need some help with it.

-

They've been done before. Tony Rumore did one on his competition version, then if I remember correctly, installed a muzzle brake with 3M bearing locker. I don't tink I'd let anyone but a professional gunsmith do it. The barrels are chrome lined,so it takes a quailty$$$ reamer to start with, then it has to be threaded on center or you'll F your pattern up. Tony's work around on the muzzle device was pretty slick as there's not enough barrel material to thread both the inside and outside diameter.

I will add to that, someone makes a low-profile thin wall internal choke reamer set, can't remember where I seen it, but it would put the Saiga right at the minimum wall thickness if it had external threads as well. Brownells maybe? CHokes were more expensive though.

-

Happy B-Day Jim!

-

Nope, just load it up. You must have a chinese? The romy drum I have doesn't allow for winding up.

-

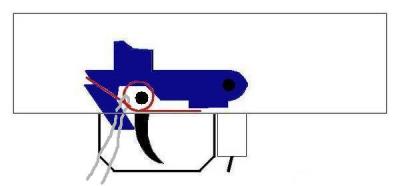

Here's a pic of what they're for.

Nice idea you all got going!

I got a pile from widgetco back in the day, just had some pop out since they don't have the locking tabs, but of you heat and flatten them on the inside they won't come out...

I'd be happy to toss in these I have left as well. Drop me an email for whoever wants them to get it started - dinzzag@yahoo.com. Probably 60 to 70 left of those. Up for grabs...

edited to add: the ones I got were 3/16" or between 4 & 5mm. Same ones maybe?

edited to add again: sometimes you need to drill the holes with a 3/16" drill bit to get them in...

-

Pretty crafty there on the buttstock guys, nice!

Did you get that new forward upper retainer to lock on?

Beautiful build!

-

Happy belated B-Day bud, hope all is good over there!

-

He didnt say the spring broke, but that it popped out of place possibly from being over tensioned.

Actually he DID, on Saturday, hence the "when we were out there" part

I am sure that you are happy to hear that it didnt break but popped out of place instead, as he noted in his post above. I know I am.

Yeah, I thought it broke when we were there because it was making a scraping sound when I spun it, but that was just the end of the spring rubbing inside.

All good now...

-

-

-

Nice Mark, how's she feeding?

-

$110 - right now. I'm only having batches of 10 done up at a time.

If they do o.k. I will invest in larger #'s and possibly get price in the $90's.

The blanks I get can be bored for either S12 or S20.

I have a set of 308/30-06 ones on order as well.

Thanks

-

Thanks dude, they are milled, but not with a cnc.

-

+1 I am stocking those hitch pins and will have 'em up on the site soon.

Much easier to remove and reinstall than e-clips.

3/16" is the proper size you want.

-

HEY! COOL!

in Dinzag Arms - DinzagArms.com

Posted

Thanks guys! Wouldn't be here without you all.

Been slowly growing it up, trying to manage stuff & do it right.

Takes a lot of time to sort through communications, but most of you all know to shoot me an email if you need anything. 99% of the time we'll get to you within a day.

Thanks to Max for letting me lurk around here & peddle some wares. Also to Jane & the mods for getting everything set up.

Keep in mind there's some old topics moved in here, some of the stuff is a couple years old. I'll get to editing those soon. Many things have changed.

For now, current products, instructions and pricing please refer to the Dinzag Arms Website.

And if you need to catch me, shoot me an email - dinzzag(at)yahoo.com - I'm usually around.

Thanks,

Brian & crew

Dinzag Arms